Products & Technologies

Back to Menu

Products & Technologies

Services

Resources

TABLE OF CONTENTS

A Letter from Ali Salehpour - Climb the Productivity Curve Faster

Leveraging the Digital Twin in Smart Microelectronics Manufacturing

STMicroelectronics Demonstrates Adaptive Endpoint Control System for 200mm CMP

Applied Materials Technology-Enabled Services Support Next-Generation Manufacturing

Maximize Output from Fleets of Tools

Industry 4.0 Reaches into the Subfab

The Last Word: Smart Transportation to Drive Semiconductor Content

Leveraging the Digital Twin in Smart Microelectronics Manufacturing

By James Moyne

Among the many tenets of smart manufacturing,[1] “digital twin” solutions represent a significant opportunity for microelectronics manufacturers to leverage existing and emerging technologies to improve quality and throughput, and reduce variability and cost.

The microelectronics industry is working vigorously to leverage the big data revolution and tap into smart manufacturing (SM) and Industry 4.0 strategies. These promise to improve integration and analytical capabilities, and enable solutions such as predictive maintenance and optimized scheduling and dispatch. One key SM tenet receiving considerable attention is the so-called “digital twin.” In this article we examine this concept and illustrate how the microelectronics industry is well-positioned for leadership in its technology development and implementation.

SCIENCE FICTION BECOMES REALITY

The term “digital twin” (DT) invokes thoughts of science fiction: Isaac Asimov; films like 2001 A Space Odyssey and I Robot; and even human cloning. So to many, the vision of a DT in manufacturing implies a computer replica of everything in the factory from components and equipment through systems, and maybe even the actions and behaviors of people. While this may indeed be a future reality, it is important to take a step back, understand how we define digital twin in manufacturing, and then assess how we can leverage this concept today and moving forward.

A generally accepted definition of DT can be found in Wikipedia, namely “A digital twin refers to a digital replica of physical assets, processes and systems that can be used for various purposes.” [2] If we break down this definition, we realize that DT is more than just replicas or models of things (as we see in movies), but also models of processes and systems. For example, in addition to a duplication of the etch system configuration, a model of an etch application process, pump health profile, or product flow at a detailed, or even high level in the fab is considered to be part of the DT family. Assuming this more complete definition of DT we can make the following statements on the state of the art and vision for DT in microelectronics manufacturing:

- The industry is already successfully employing DT components fab-wide. Applied Materials has been working with customers to realize these DT components in a way that can provide the best customized benefits.

- The extraordinary scale and precision required to repeatably create microelectronic devices make this kind of manufacturing one of the most intricate and sophisticated in the world, and we have had to develop DT technology to meet our manufacturing needs. As such, our industry is arguably a leader in driving aspects of DT technology advancement.

- The industry is beginning to explore and benefit from abstracting and combining these DT components.

- The industry has a realistic vision and roadmap for DT that will provide for significant improvements in quality, throughput and reductions in variability and costs over the next 10 years.

In the remainder of this article each of these points will be explored in detail, along with case studies of DT successes.

DIGITAL TWIN IN TODAY’S FABS

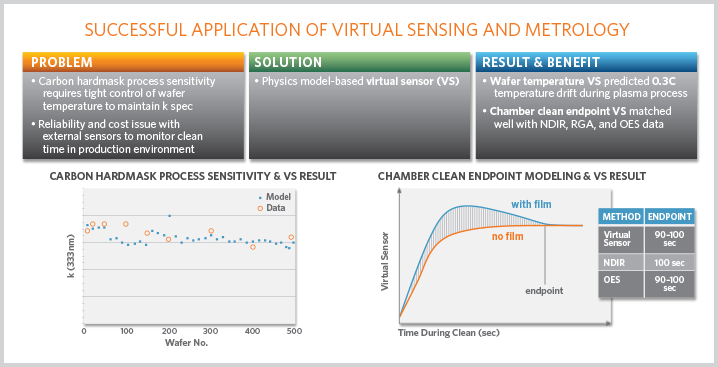

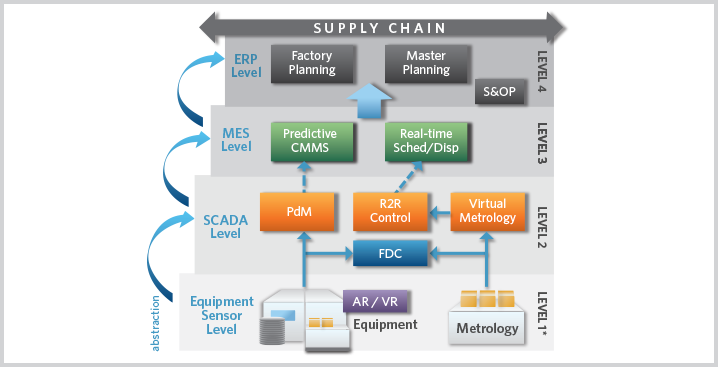

Without realizing it, many fabs today are already at the forefront of the revolution, having pioneered many DT technologies and providing testaments to DT success. Our existing pervasive technologies, such as run-to-run (R2R) control and real-time scheduling and dispatch (S/D), and emerging technologies such as predictive maintenance (PdM) and virtual metrology (VM) are key members of the DT family. This section examines how these technologies are being leveraged in today’s fabs.

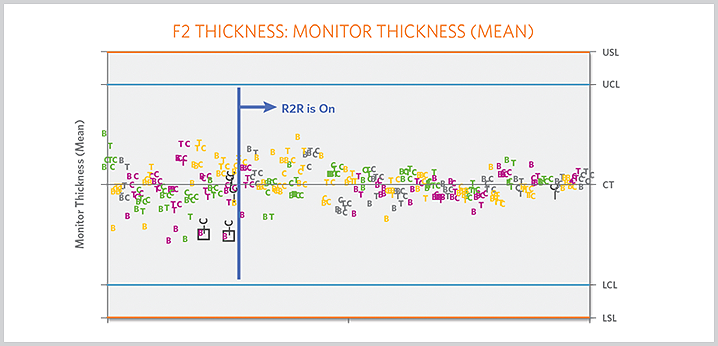

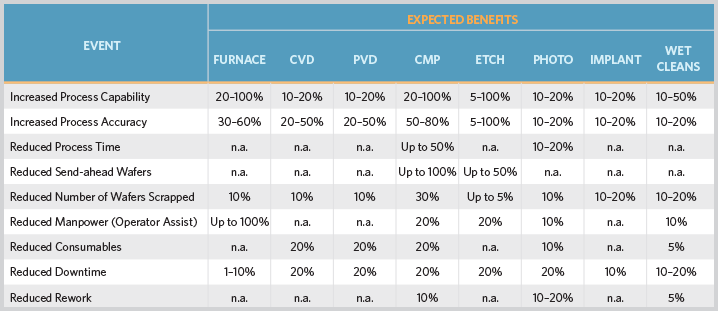

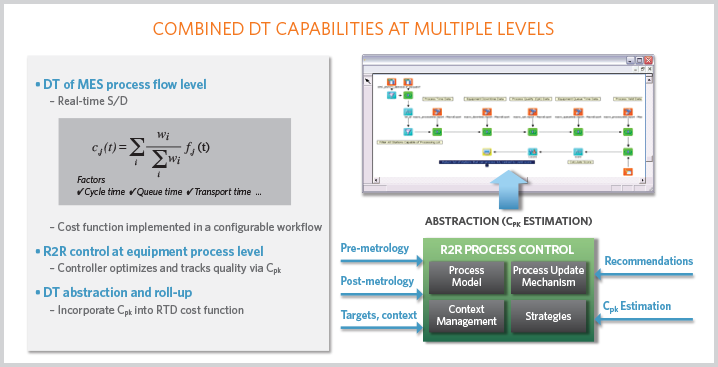

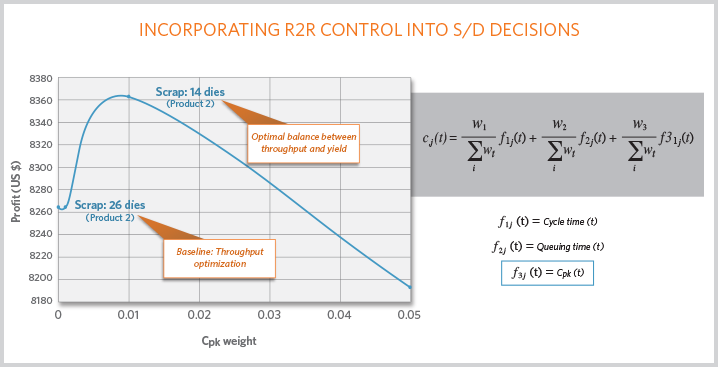

R2R control—In the early 1990s, model-based process control, known as R2R control in our industry, was first deployed on semiconductor manufacturing technologies such as chemical-mechanical planarization (CMP).[3] It was successfully demonstrated to improve process capability by improving control and reducing variability of qualities such as thickness and uniformity. Today R2R control is pervasive in most fabs and is a requirement in many front-end processes. Figure 1 illustrates the benefits that R2R control can provide, while table 1 summarizes the R2R control capabilities that are widely deployed in microelectronics front-end technologies today.[4] The microelectronics industry’s success with fab-wide model-based process control solutions positions us as a technology leader, and we continue to innovate in this arena, providing solution extensions such as non-threaded R2R control, and combining R2R control with capabilities such as S/D.[5,13]