半导体 (Semiconductor)

解决方案与软件

Nokota™ ECD

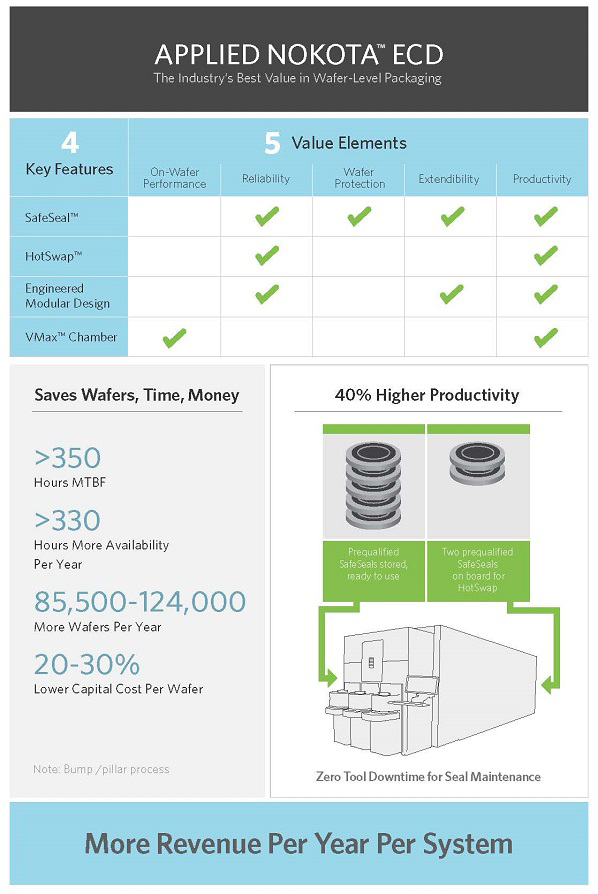

The Nokota system expands the Applied Materials suite of electrochemical deposition systems with a high-productivity advanced packaging tool that delivers best-in-class performance for the full range of plating steps used in diverse packaging schemes. These range from flip chip and wafer-level chip-scale packages to 2D and 3D fan-out, 2.5D interposer designs, through-silicon via, and packaging for IoT, sensors, 5G, automation, and power devices. Systems are available for 200mm and 300mm operation, and for simultaneous processing of 200mm/300mm wafers on a single system. Copper, tin/silver alloy, nickel, gold, tin, and palladium are the metals most commonly used, although others can be accommodated.

The system is designed to deliver superior on-wafer performance, reliability, wafer protection, extendibility, and productivity. Combined, these attributes make possible more than 330 additional hours of production per year, making the Nokota system the plating product with the lowest cost of ownership and highest productivity on the market.

The unique SafeSeal™ assembly ensures ultimate protection for every wafer, sealing each one prior to processing and protecting it throughout a single- or multi-metal plating sequence. Pre-process seal leak testing and post-process cleaning and inspection ensure that each wafer is protected during the plating process. Also unique in the industry, the HotSwap™ mechanism that operates outside the process chambers enables automated SafeSeal replacement in parallel with uninterrupted production. Combined, these aspects of system operation proactively prevent wafer scrap and completely eliminate tool downtime for seal maintenance and seal replacement. VMax™ process chambers ensure maximum mass transfer rate and uniformity that produces optimal plating rates with high uniformity. An in-chamber rinse is integrated into each VMax chamber, enabling intermediate rinsing between plated films.

The modular Nokota system delivers productivity well beyond that achieved by other systems on the market by featuring high-reliability components and a unique single-chamber configurability (vs. the typical chamber pairs) for maximum flexibility. Nokota systems are extendable from R&D through pilot production to high-volume manufacturing. Rapid (<1 day) reconfiguration makes the Nokota system ideal for the growing number of fabs handling varying product mixes and capacity demands.

- 1 / 4

- 2 / 4

- 3 / 4

- 4 / 4