Products & Technologies

Back to Menu

Products & Technologies

Services

Resources

Control and Diagnostics Innovation in the “New Normal”

By David Lammers

HIGHLIGHTS FROM THE APCSM 2020 CONFERENCE

The Covid-19 pandemic has accelerated collaborative-while-remote development in the semiconductor industry because travel restrictions and improved cloud security have encouraged more semiconductor fabs to allow controlled visibility into fab data, according to participants at the Advanced Process Control and Smart Manufacturing (APCSM) 2020 Conference, held virtually in early October.

“Whether we deliver the best solution remotely or on site, we do what is needed. It is all part of the new normal,” said Amos Dor, general manager of pharma solutions at Applied Materials.

James Moyne, an associate research scientist at the University of Michigan and a consultant for Applied Global Services® (AGS), said he has observed a general lessening of restrictions on sending fab data to the cloud because most travel is currently banned by corporate policies. “There are definitely more cloud-based solutions. In the short term it has been pushed forward by the COVID-19 situation. Cloud security has improved, and the experts can’t be in 10 places at the same time,” said Moyne, who co-chairs the APCSM Conference along with Brad Van Eck and John Pace, formerly of SEMATECH and IBM, respectively.

On the technical front, the two-day APCSM 2020 conference featured several papers on run-to-run (R2R) control that uses a combination of physical and statistical models, while other presentations described more traditional machine learning approaches. Applied Materials technologists contributed six technical papers, including three highlighted in this article.

REMOTELY PREQUALIFYING SOLUTIONS

A key challenge that has been plaguing cost-effective deployment of APC solutions over the past decade has been the inability to assess and debug solutions in their integration environments prior to deployment. Dor said Applied has taken a significant step in addressing the challenge by developing a computer-integrated manufacturing (CIM) simulation and pre-validation environment called CIMLab.™

CIMLab creates a digital twin of the fab environment, or what Dor called “a mini simulated fab,” using field data. “We like to have three years of historical data, but we will take whatever the customer will send us. We want to be as close as we can to the customer side.”

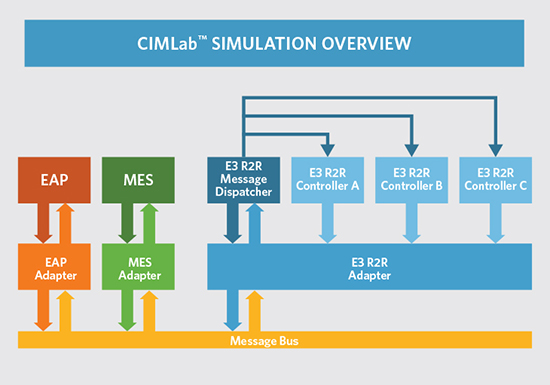

CIMLab was described in a paper entitled “A CIM Simulation Environment to Support Developing and Testing R2R Control Solutions Prior to Deployment” that was presented by Applied’s Pratik Kotcher. The paper details work by Kotcher and his fellow AGS application engineers. According to Kotcher, CIMLab uses manufacturing execution system (MES) and equipment automation program (EAP) simulations for testing, based on the Applied Materials 300works™ platform, while the R2R control solution is implemented on the Applied E3® platform (Figure 1).

Figure 1. CIMLab uses manufacturing execution system (MES) and equipment automation program (EAP) simulations on the Applied Materials 300works platform, while run-to-run (R2R) control is implemented on the Applied E3 platform. (Source: APCSM 2020)

“The challenge when we do R2R controllers is that we don’t always understand the customer’s environment. By simulating within CIMLab, we can create a digital twin and end up with better results,” said Dor. Customers create scenarios of how they plan to use R2R, and Applied simulates these test cases in actual manufacturing scenarios, tuning recipe parameters and simulated metrology data before the R2R controllers are shipped to the customer.

“When we build the simulations in CIMLab, we don’t need a lot of time and it enables us to create a better debug before we deploy the solution. It has been successful with customers around the world,” Dor said.

IMPROVING FAULT CLASSIFICATION

Moyne said that while many vendors offer fault detection and classification (FDC) tools, most of those tools are “big D, little C” because they have adequate detection but “really weak fault classification.” Deepak Sharma, a consultant for algorithm development at Applied, delivered a presentation at APCSM entitled “Implementing Wafer Classification for Fault Detection and Classification Using Clustering Classification.” As a co-author along with nine other Applied Materials employees, Sharma described a clustering framework that allows the use of multiple algorithms and is extendable as new algorithms become available.

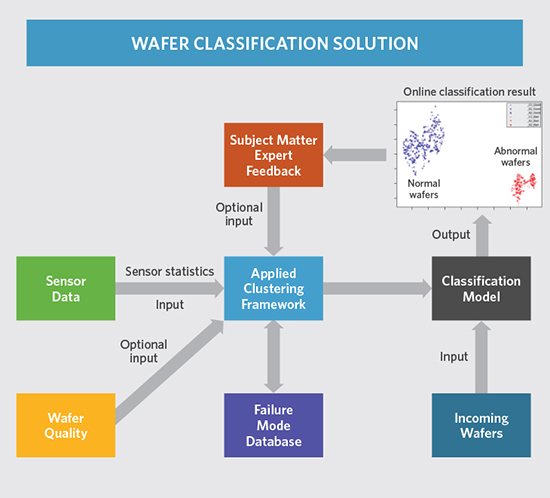

The Applied clustering framework is a tool that can be used for fault classification, preventive maintenance (PM) characterization, chamber matching and chamber variance analysis, and process quality analysis. After a PM it can perform maintenance characterization to differentiate between a good or bad maintenance cycle, ensuring that when the tool is brought back up the clustering framework functions properly and does not have to be taken back down again. The clustering tool can also indicate the quality of a maintenance routine, and if the maintenance failed, indicate why (Figure 2).

Figure 2. A wafer classification system uses a clustering framework to detect, classify and characterize wafer groupings. (Source: APCSM 2020)

Sharma argued that traditional statistical process control (SPC) focuses more on process monitoring, not on classification. Traditional FDC lacks support for multi-class wafer behavior classification, beyond a relatively simple “normal vs. abnormal” rating. By using a clustering framework to detect, classify, and characterize wafer groupings, the tool can determine the group to which the wafer belongs. It identifies the key sensors responsible for wafer groupings using a root-cause analysis capability to determine which sensors were employed to detect a particular pattern.

“The goal of this effort is to use machine learning, with or without subject matter expertise and wafer quality data,” Sharma said. The clustering tool has a failure mode database that stores different patterns, detects what a particular wafer’s pattern looks like, and classifies it. Moyne said traditional FDC uses “lots of charts, while the approach described by Sharma makes it simpler to find multi-class wafer behavior and differentiate it using clustering. It more efficiently separates the good or bad wafers, and determines what contributes to a bad wafer and how to fix it. The clustering tool adds more functionality, with lower setup times, and gives operators the ability to identify abnormalities.”

IMPROVING DIFFUSION FURNACE UNIFORMITY

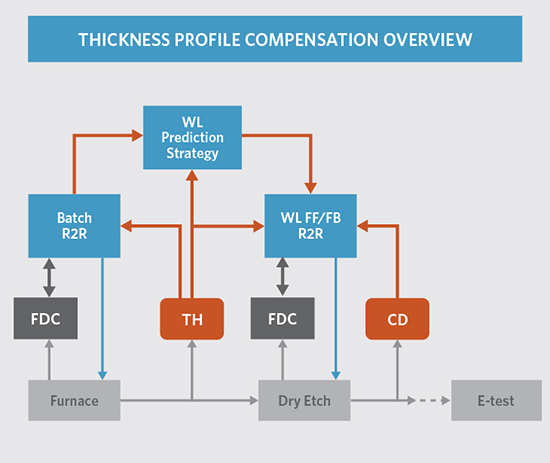

A presentation on R2R control of a diffusion furnace by Applied’s Shijing Wang combined SPC and physical modeling in a hybrid approach. Wang, the global product manager for the Applied E3 engineering system, presented research on how to combine multi-physics modeling and machine learning (ML) techniques to predict the wafer thickness of each boat slot in a batch diffusion furnace. The work, implemented in the Applied SmartFactory® R2R platform, uses a physics-based model to show the thickness profile of a vertical diffusion furnace with a 5-zone (or 4-zone) heater design. The non-uniform thickness profile in each heater zone, or across all five heater zones, cannot be eliminated, Wang said, because of temperature uniformity problems and depletion effects.

The recipe adjustments by a furnace R2R controller keep just the thicknesses of five monitor wafers on target, so the controller improves the thickness uniformity along the boat slots “only to some extent.”

The hybrid tool uses new metrology data as it becomes available to update the parameters of the multi-physics model, which predicts the wafer thickness of each boat slot in the furnace. A design of experiments (DOE) uses multiple Gaussian process models to profile a furnace heater, adjusting from furnace to furnace. The wafer-level, feed-forward R2R controller removes the wafer-level thickness variations from the diffusion furnace at the downstream etch process step, resulting in less scrap and improved yield (Figure 3).

Figure 3. A wafer-level, feed-forward/feed back (WL FF/FB) R2R controller can be used to detect the thickness (TH) introduced by a diffusion furnace. (Source: APCSM 2020)

The overall goal is to augment the skills of the subject matter experts with powerful software. “Traditional FDC takes a lot of charts,” Moyne said. “We have figured out how to make it simple.”

For additional information contact michael_d_armacost@amat.com or jmoyne@cantoncontrols.com

Amos Dor, General Manager of Pharma Solutions, Applied Materials

James Moyne, Associate Research Scientist at the University of Michigan