Products & Technologies

Back to Menu

Products & Technologies

Services

Resources

Smart from the Start: Fully Automated Fabs Deliver Competitive Advantage

By David Hanny & Shekar Krishnaswamy

Fully automated factory systems are fast becoming a necessity in semiconductor manufacturing, given today’s ultra-competitive markets, shorter product life-cycles, the growing use of semiconductors in new applications and the need to quickly set up greenfield fabs around the world. They enable manufacturers to achieve significantly better yields, output, cycle times, quality and flexibility, all while using production assets more efficiently and reducing overall costs compared to fabs which are only partially automated.

However, most current semiconductor-industry automation systems are a mix of internal and specialized products from a variety of suppliers. They are heavily challenged to reduce human- and other errors, accelerate ramps, and achieve maximum manufacturing flexibility as well as a complete, fully integrated platform. Systems that are non-integrated, and which use point solutions, are faced with higher costs, higher risk, and have a decreasing ability to adapt to emerging solutions.

For example, here are the CIM considerations and applications required for a fab’s startup phase:

- Connect tools with an equipment integration application to gather data and status from the tool; and initiate recipe management and tuning. This enables the yield management system (YMS) to better diagnose outliers.

- Ensure that the core factory infrastructure is operational with a manufacturing execution system (MES) and material control system (MCS);

- Establish effective planning capabilities to maximize the fab’s ability to meet customer orders.

- Measure wafer characteristics and validate conformance to specs with statistical process control (SPC) and defect management;

- Set up an equipment maintenance management system (MMS) application to service each tool to maximize its yield and output;

In the ramp phase, run-to-run (R2R) advanced process control (APC) is needed to reduce process variations and improve conformance to key performance indicators (KPIs). The “golden question” is, what lot to run at any given time? A mature and effective scheduling and dispatching system provides decision logic that enables fab performance objectives to be met, which increases the fab’s operational control, dramatically reduces variability, and “line-balances” the factory.

For example, one Applied customer realized a 5–15% increase in cycle time and plant capacity in the ramp phase as a result of Applied Materials scheduling and dispatching solutions that eliminated hidden constraints, excessive tool dedication, excessive priority lots/changes, and time spent on dispatching and planning decisions.

When it comes to high-volume manufacturing, solutions must embrace automated operation for the highest performance. The Applied SmartFactory® FullAuto capability minimizes touch points, unnecessary handling and white space. It uses fault detection and classification (FDC), multivariate mathematical optimization, predictive solutions and dynamic scheduling to achieve maximum efficiency in high-volume production. This increases the ability to match the right lot at the right time with the right tool, positively impacting both yield and output KPIs. Finally, in the mature, cost-control phase of production, integrated solutions can adjust easily to changing business strategies and conditions, and the often-expensive cost to create and maintain new systems can be reduced.

A Proven Manufacturing Partner

Applied Materials is the leading semiconductor-industry automation solution provider, with a team of 500 experts (150 in China alone) and three decades of experience automating semiconductor fabs. The semiconductor and display industries are using SmartFactory to increase fab process control, line control and WIP quality, and to improve the performance of fab logistics and supply-chain interaction. The reduction in variability enables a higher degree of success for discrete solutions and an increased ability to attain predictable yield and output results.

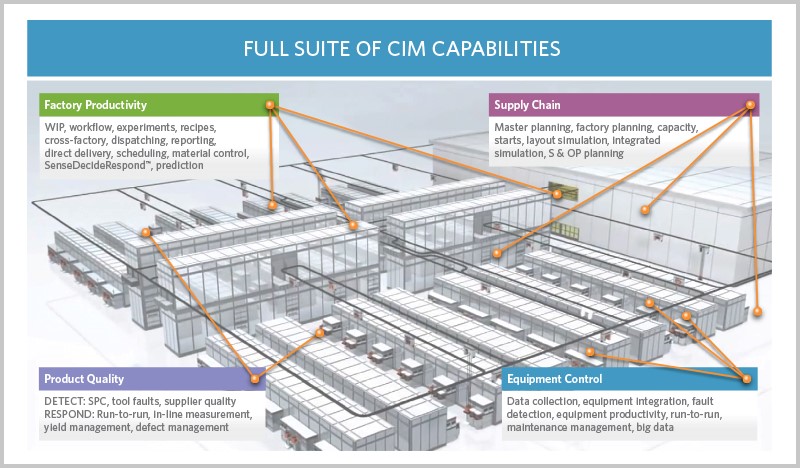

The Applied SmartFactory suite includes a wide breadth of mature capabilities (see figure 1).

Figure 1. The fully integrated Applied Materials SmartFactory automation suite spans factory productivity, equipment control, product quality and supply chain management.

Conclusion

Semiconductor manufacturing, assembly and test are growing more complex, while end-markets are transforming. Add to that the establishment of greenfield fabs in different parts of the world and an interesting market dynamic is evolvingone that requires manufacturers to quickly adopt integrated solutions.

Integrated automation solutions that make optimal use of data to synchronize manufacturing planning, control and operation can help users achieve their goals for better device performance, yield, revenue, profitability, and ultimately, greater market share.