Back to Menu

製品情報

Applied Sonetto™

Shingling Technology

In a standard photovoltaic module, a gap is maintained between the cells to provide clearance with the interconnecting ribbon and minimize the mechanical and thermal stresses between the cells from daily exposure to the environment. These gaps are inactive areas of the module, reducing the output power the performance of the module.

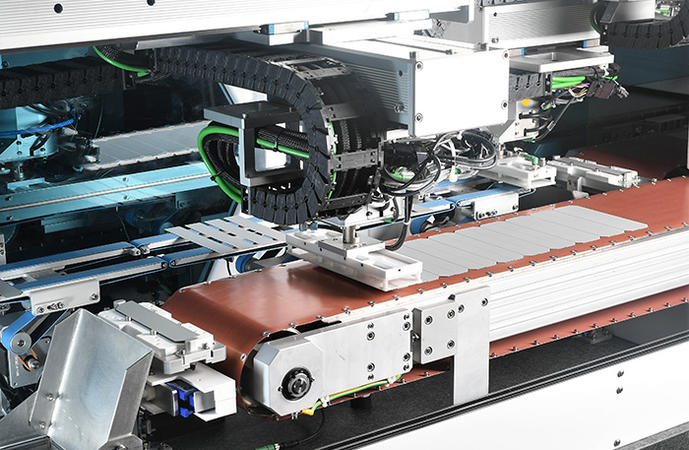

Shingling is the most efficient technology to connect cells to increase the module's active sunlight absorption density, resulting in higher power output. Cells are sliced into many strips along the busbars and then interconnected by placing one strip directly on top of the other with a minimal overlap eliminating the ribbons. Electro Conductive Adhesive (ECA) is used to provide the electrical connection between the strips. The result is a module with almost no gaps.

The shingling approach provides several advantages compared to standard PV modules:

- Higher Power per square meter

- Lower ohmic losses

- Less energy loss due to shading

- Reduced busbar failures

- Lower processing temperature

- Better mechanical performance

- Better aesthetics

For more information, contact solar@amat.com.

- 1 / 4

- 2 / 4

- 3 / 4

- 4 / 4