Products & Technologies

Back to Menu

Products & Technologies

Services

Resources

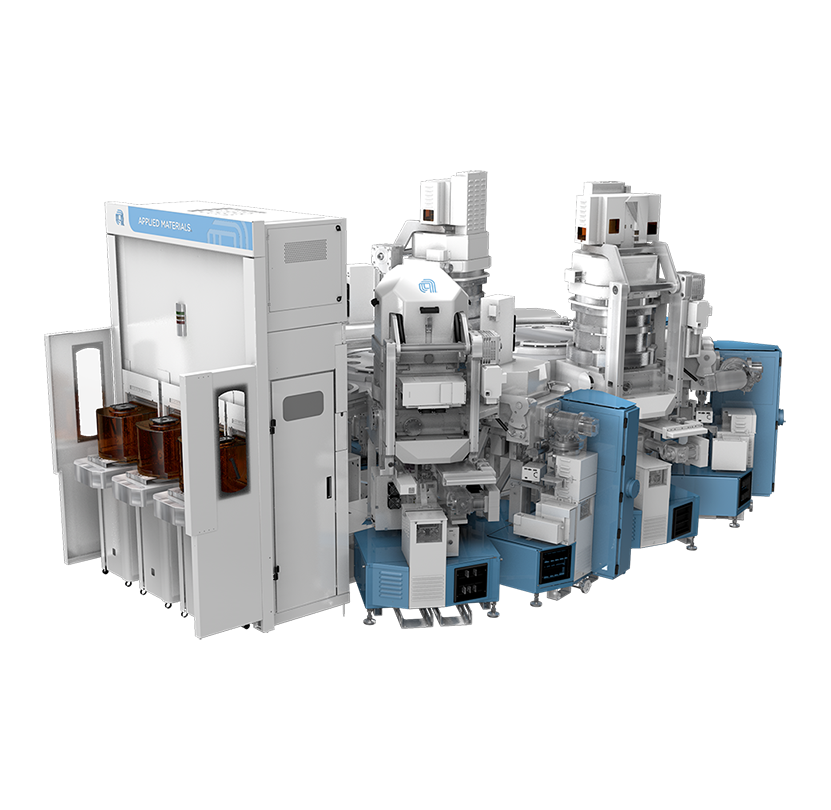

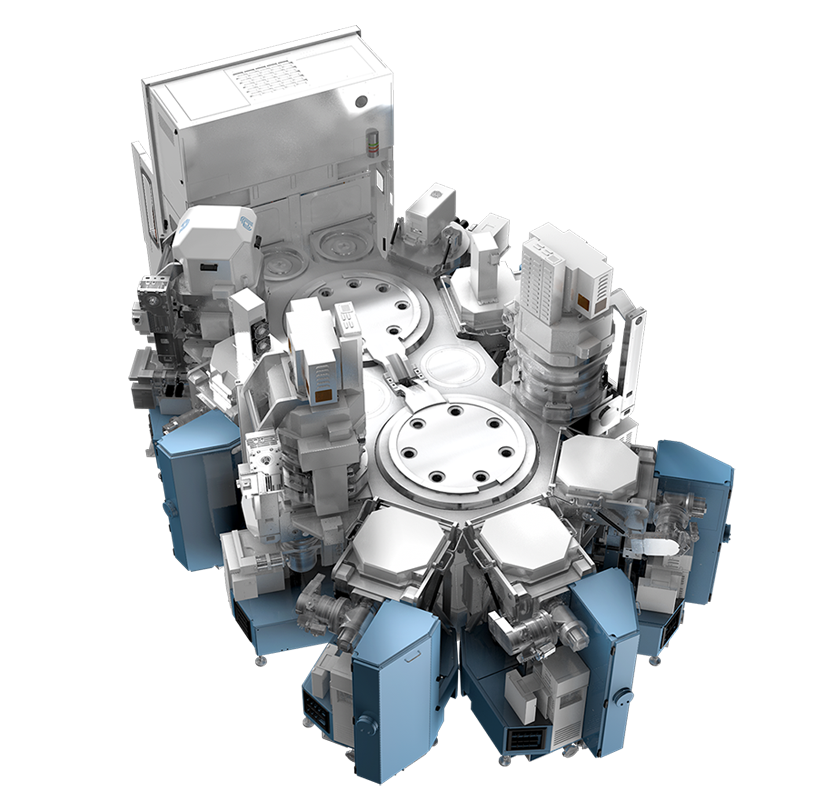

Endura CuBS Volta Ruthenium CVD

Increasing transistor density demands smaller and smaller wiring, straining requirements on all critical processes involved in chip manufacturing. The Applied Endura™ CuBS (Copper Barrier/Seed) IMS™ with Volta™ Ruthenium CVD provides a solution to reduce power consumption, increase performance and enable area scaling in a single integrated material solution.

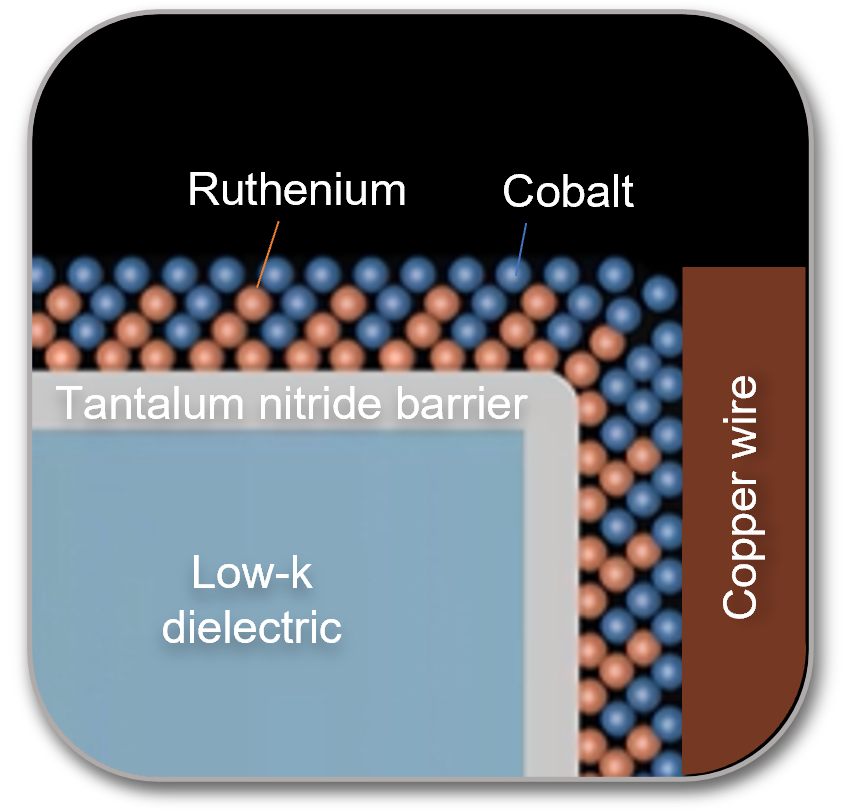

Methods for filling interconnects with copper at the most advanced nodes relies on reflow technology, using anneals to flow copper from the wafer surface into the wiring trenches and vias. This reflow depends strongly on the liners that copper must flow upon. Traditional methods use a CVD cobalt film for this purpose in larger devices. However, this film is too thick for 3nm and smaller devices, and compromises both yield and resistance.

With the ruthenium cobalt (RuCo) binary liner, Applied Materials scales the thickness of this critical layer to less than 20Å and provides more volume for the conductive copper wiring. Additionally, the interfaces from this novel film greatly improve the reflow mechanism and achieve yield on the smallest interconnects in development.

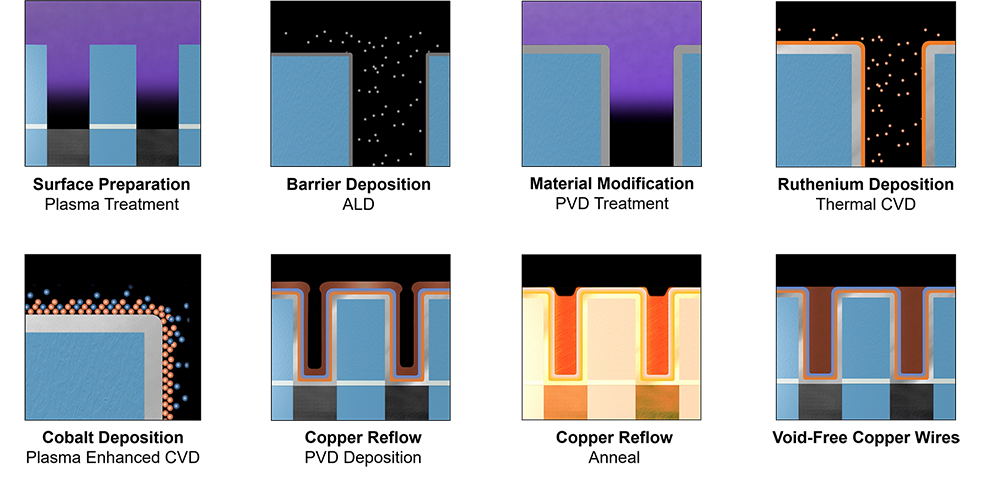

CuBS Copper Wiring Process Flow

- 1 / 4

- 2 / 4

- 3 / 4

- 4 / 4