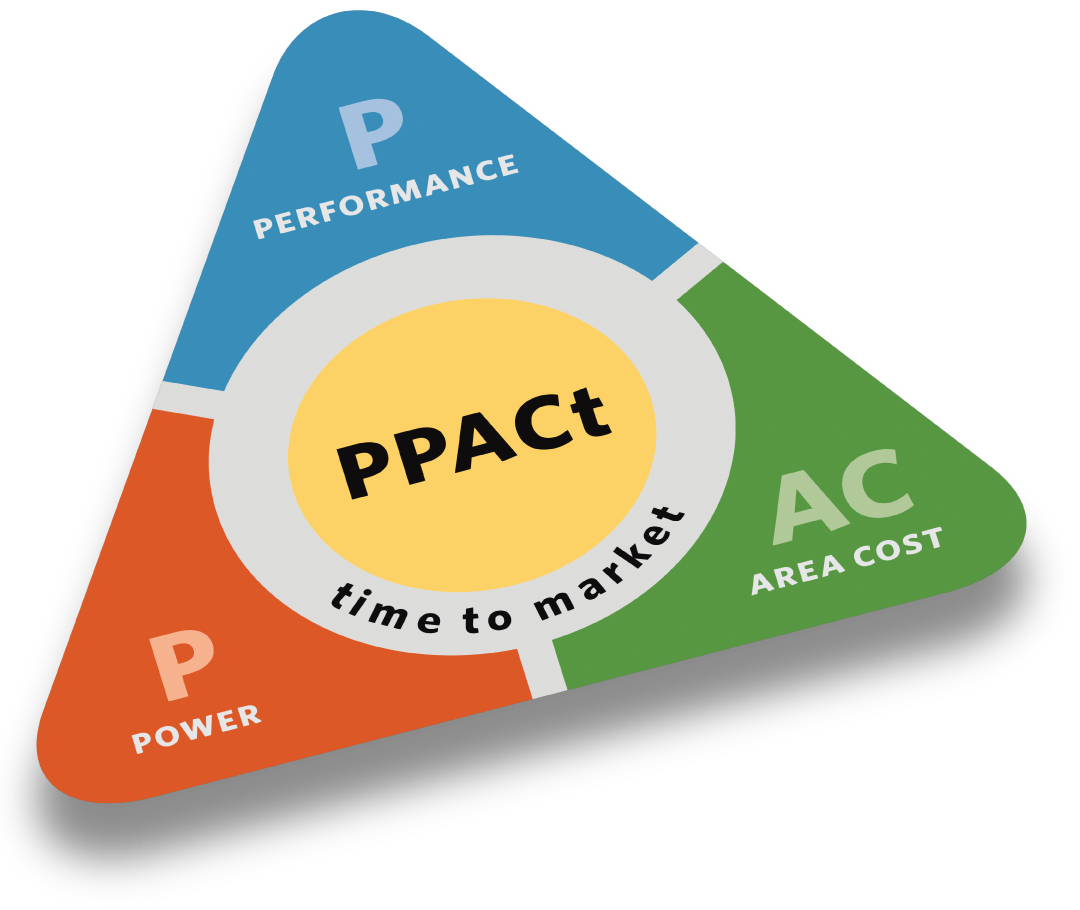

PPACt

Power, Performance, Area, Cost, Time to Market

PPACt Enablement Company™

The Internet of Things, Big Data and artificial intelligence (AI) demand rapid, dramatic improvements in chip performance, power, area, cost and time to market (PPACt). This materials engineering challenge is the force behind our industry’s new playbook.

Applied Materials is committed to accelerating this new PPACt playbook for our customers and partners. We have the broadest and deepest portfolio of products for delivering materials engineering innovations to the market. This portfolio includes the ability to create and deposit, shape and remove, modify, analyze, and connect materials and devices in new ways.

As traditional Moore’s Law scaling slows, the industry needs new ways to increase chip performance, and increasing chip performance while lowering power consumption is a growing challenge. Innovations like our Integrated Materials Solutions combine multiple processes with customized metrology and sensors in a single system to help our customers create faster, more efficient chips.

As the industry moves to smaller process nodes, the amount of physical space available on a chip to pull transistors closer together is disappearing. Applied has a suite of materials and materials-shaping solutions that enable creative ways to simultaneously and cost effectively scale area and cost while improving power and performance.

Time to market is critically important in the semiconductor industry. Getting new chip designs to market faster benefits the entire technology ecosystem and can be worth billions of dollars to our customers. Our investments in state-of-the-art digital infrastructure bring together sensors, metrology, data science, machine learning and simulation to help us shorten product development cycles; speed up transfer of new technologies from lab to fab; and optimize cost, output and yield for our customers in volume production.

PPACt advancements are critical to the chip industry’s future and with our innovative and unique materials engineering solutions, Applied is the PPACt Enablement Company.

“A key part of our strategy at Applied Materials is to be the PPACt enablement company™ for our customers. We offer the broadest portfolio of products that deliver improvements in chip power, performance, area, cost and time-to-market. As traditional Moore’s Law scaling slows and becomes more expensive, new design and manufacturing paradigms are being adopted by chipmakers and systems companies to advance their PPACt roadmaps.”

Nirmalya Maity, Ph.D.

The Future of Logic Depends on Heterogeneous Design and Integration

The Internet of Things (IoT), Big Data and AI are exerting new demands on performance, power, area-cost and time-to-market (PPACt) that exceed the bounds of classic Moore’s Law scaling.

Innovations in eBeam Metrology Enable a New Playbook for Patterning Control

The patterning challenges of today’s most advanced logic and memory chips can be solved with a new playbook that takes the industry from optical target-based approximation to actual...

Expanding the Ecosystem for Hybrid Bonding Technology

A key part of our strategy at Applied Materials is to be the PPACt enablement company for our customers. We offer the broadest portfolio of products that deliver improvements in chip power, ...