Products & Technologies

Back to Menu

Products & Technologies

Services

Resources

Blog Archive

Optical Circuit Switches Show Promise for More Energy-Efficient AI Data Centers

Applied Recognized for Leadership in Ethics and Compliance

Applied Materials Employees Raise Millions to Fight Hunger Across North America

Accelerating Defect Inspection for More Reliable Automotive Chips

Semiconductor R&D Leaders Share Vision for Accelerating Advanced Packaging

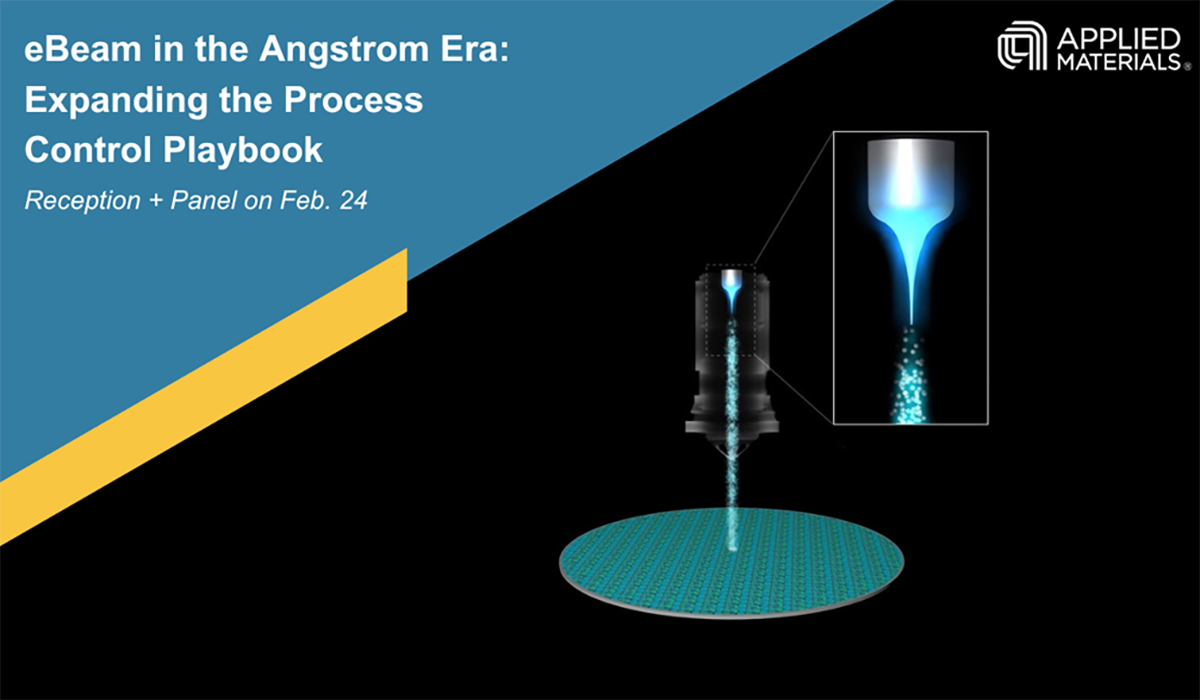

Expert Panel To Explore Advances in eBeam Technology

Alongside the 2025 SPIE Advanced Lithography + Patterning conference in San Jose, CA, Applied Materials will bring together a panel of experts from across the semiconductor ecosystem to explore how chipmakers are increasingly using electron beam (eBeam) technology to continue pushing chip scaling to its limits.

Advanced Packaging Enters a New Dimension

Applied Materials recently hosted a panel during IEDM in San Francisco titled, “The Future of Advanced Packaging: 3D is Here, Now What?” In a lively discussion, technology leaders from AMD, Intel, Cadence and Applied offered their perspectives on a wide range of topics – from the key technology building blocks that will enable next-generation AI chips, to how the ecosystem can work together to accelerate the pace of innovation.

Happy Holidays From Applied Materials

Happy Holidays to all of our readers, and we wish you a wonderful 2025! This year we celebrate our vision to Make Possible® a Better Future. Thanks to connected devices and cutting-edge technology, we're heading into a new era of innovation and togetherness.

Celebrating 30 Years of Display Innovation

While Applied Materials is best known for providing the machines that produce the world’s logic and memory chips, we also have a long history of using our differentiated materials engineering capabilities to solve technology challenges in adjacent end-markets.

Bringing eBeam Review to Compound Semiconductors

The power electronics industry has seen a resurgence in the past two decades – driven first by the advent of specialized power management chips for smartphones and tablets, and more recently by the major global transition to renewable energy sources and electric vehicles. At the heart of this transition lies the power semiconductor device, which modulates the flow of electrical energy to suit the demands of the application.

Implant Innovation Enables the Compound Semiconductor Roadmap

AI may have taken center stage among the drivers for chip industry growth, but there is another global inflection fueling the semiconductor roadmap: the clean energy revolution. Featuring major structural shifts to renewable energy sources, smart grid technologies and electric vehicles, the star player in clean energy is the power semiconductor, which controls and converts electrical energy to supply power for a wide variety of electronic devices.

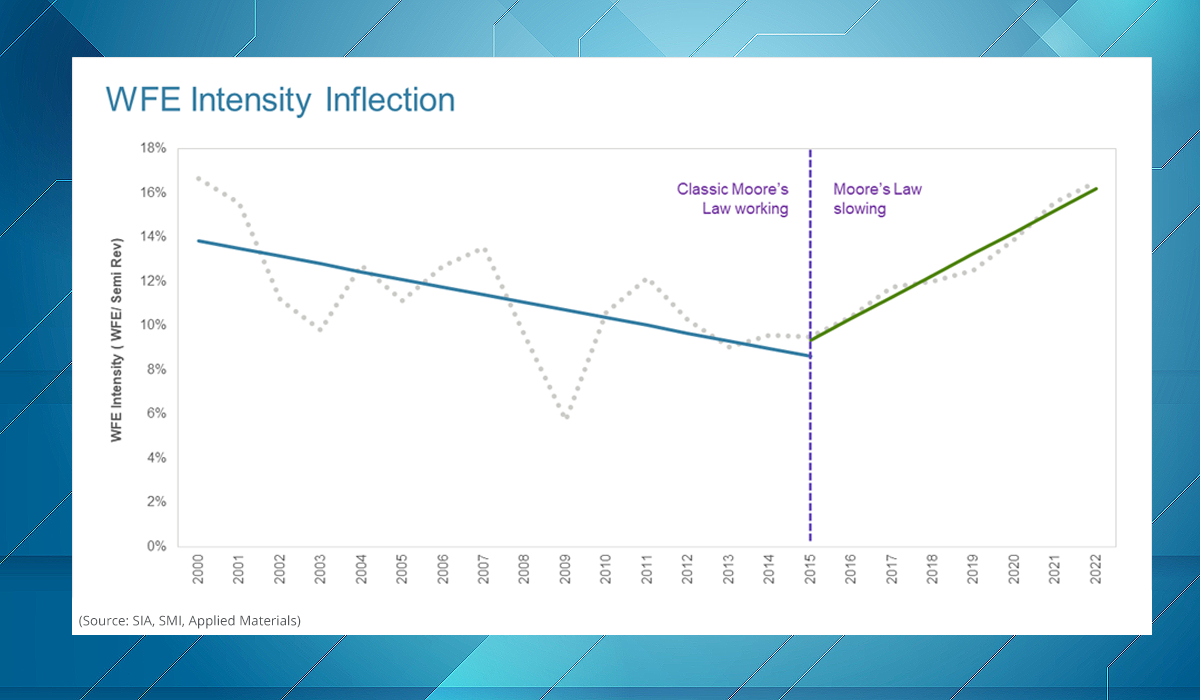

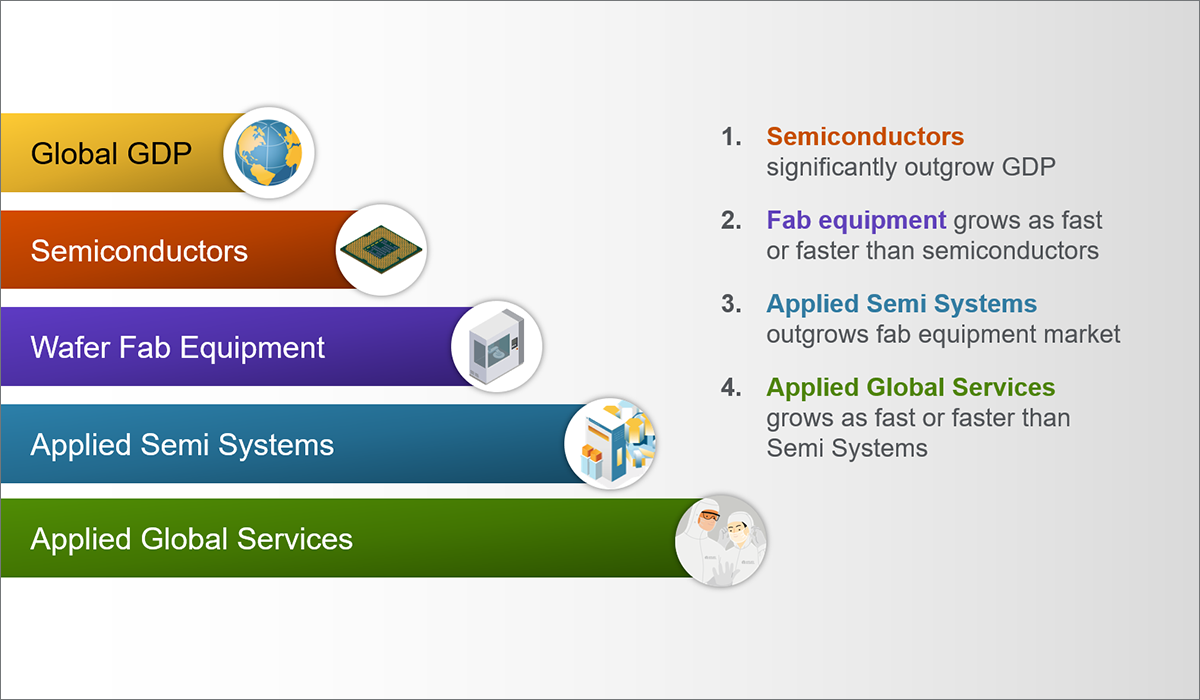

Understanding the Inflection in Wafer Fab Equipment Growth

Materials Engineering: The True Hero of Energy-Efficient Chip Performance

Applied Materials Employees Rally Together for Environmental Sustainability

The Race for AI Leadership is Fueled by Materials Engineering

Beyond Backside Power: Scaling Chips to 2nm and Beyond Also Requires Frontside Wiring Innovations

Materials Innovations Can Help Make Quantum Computing a Reality

Wafer Fab Equipment Positioned for a New Wave of Growth

Power-Hungry AI Applications Demand More Energy-Efficient Computing

While the semiconductor industry has historically driven remarkable improvements in performance-per-watt, the rise of power-hungry AI data centers is pushing the need for energy-efficient computing to an entirely new level.

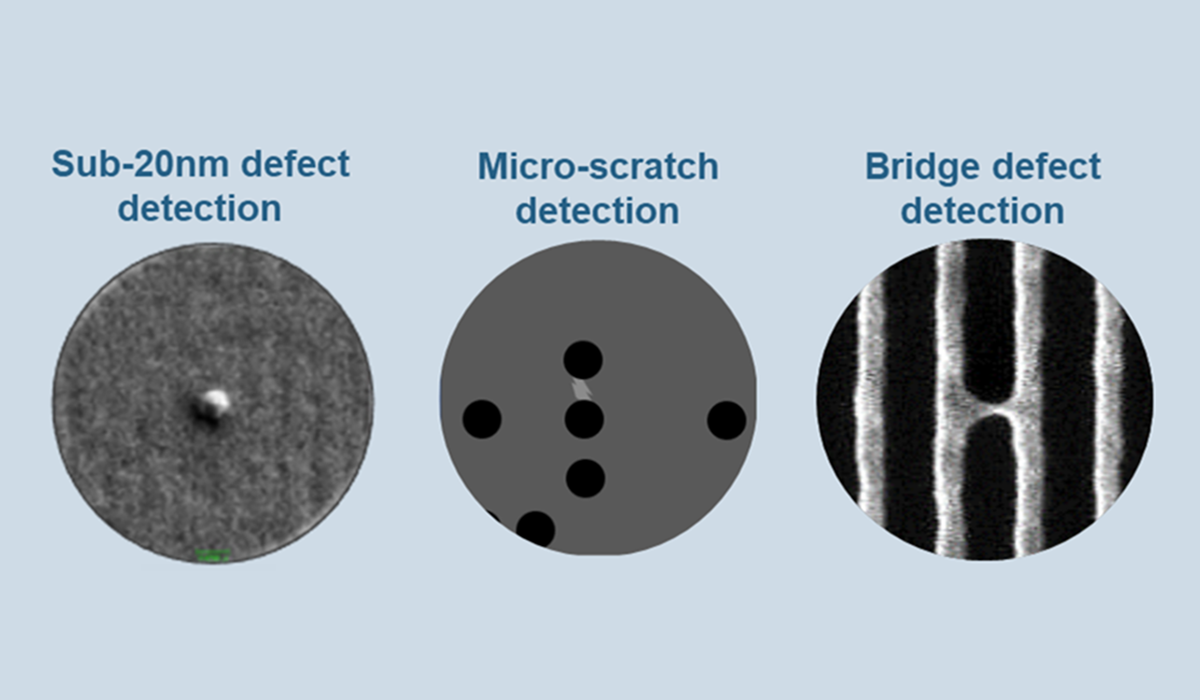

Advanced Logic and Memory Need New Tools for Optical Wafer Inspection

Celebrating Innovation: Dr. Om Nalamasu Receives the 2024 IRI Innovation Leadership Award