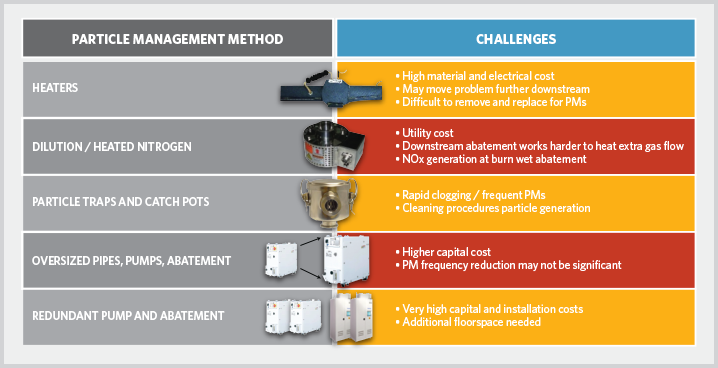

Figure 2. The figure shows commonly used abatement solutions for chamber effluent. They are not optimized for the increasingly difficult exhaust-management challenges of today’s fabs.

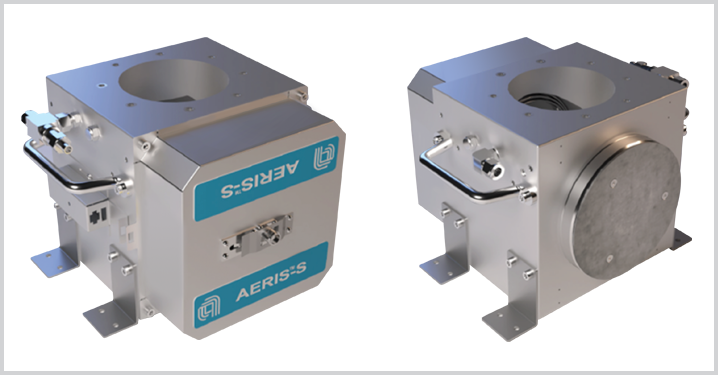

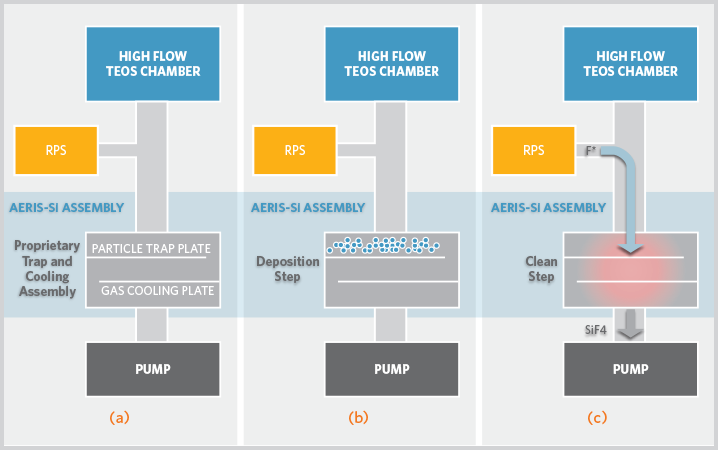

In contrast to conventional systems, Applied’s pre-pump Aeris-S and -Si plasma systems actually prevent the accumulation of solids in the foreline and pump from the outset. At the same time, they reduce the amount of potentially dangerous chemicals flowing through the exhaust system. The Aeris systems do this by using plasma and compounds in the effluent itself to convert precipitated solids and by disassociating complex molecules, instead of simply trying to improve the movement of solids and chemicals to end-of-line abatement.

Also, having the Aeris units located upstream of the pump enables them to work with the actual process gas stream. This is a much smaller, more concentrated gas volume that can be treated more effectively than large amounts of post-pump waste gas.

Applied Aeris units have significant capacity and process window advantages, with high total flow rates of 5–100 slm (standard liters per minute) and vacuum pressures of 100 mTorr–5 Torr. They can handle dielectrics, metals and corrosives in chamber effluent with high reliability, have a small physical footprint (or no added footprint at all, in some configurations), and are adaptable for evolving applications.

AERIS-S TREATS “DIRTY” GASES

Applied’s Aeris-S plasma abatement system (figure 3) is an all-purpose solution that can effectively handle high flow rates of even the dirtiest streams of chamber effluent, i.e., those most likely to lead to accumulations of solids, including potentially hazardous materials. It is designed for use with waste gas that may contain: