Moving to a New Level of Intelligent Manuacuting

By David Hanny

Semiconductor manufacturing over the past few decades has moved through several levels of technology, with each transition leading to lower costs and higher fab productivity. Now the industry is entering yet another change cycle, driven by increasing semiconductor quality requirements to meet the demands of IoT applications.

Within the walls of the factory, a new level of intelligence is being enabled by technologies such as 5G wireless, artificial intelligence (AI), more powerful processors, cloud-based data analysis, virtual and augmented reality, and integrated knowledge networks.

Together with new software applications, these technologies are driving the semiconductor manufacturing industry toward what is variously referred to as Industry 4.0, smart manufacturing, or the industrial internet of things (IIoT).

Whatever the name, today we are beginning to see the factory differently—in a virtual way—to make decisions about the best ways to manage it. The goal? To continually feed data into a knowledge network, then leverage that data to make intelligent decisions.

The evolving technologies pushing us toward intelligent manufacturing are truly astonishing: 5G networks so fast we can download a movie in four or five seconds; AI processors 50 times more powerful than today’s already-amazing graphics processors; and the potential for strategies such as cloud-based computing with maturing security capabilities poised to foster cost-effective collaborative problem solving and data analysis.

The Gradual Evolution of Automation

Think back to a time—not many years ago—when workers in fabs moved carts, pushed buttons to start up equipment, and tracked WIP on spreadsheets. Gradually, fabs moved to a new level, with the ability to aggregate data from the equipment, automate material handling systems, and implement advanced process control (APC) capabilities such as run-to-run control and fault detection.

Next, the industry advanced to a level where heuristic intelligent systems began to take control of factories, with measurably positive benefits. However, while the industry strived for a higher level of automation control, limitations began to appear. Many companies continued to use existing technologies that lacked enough compute power, bandwidth, data aggregation, and filtering to move to these higher levels of automation. Today, many in our industry are seeking a path that will allow them to transition from their current mix of manual control and automation-initiated control to full automation.

Adopting change is a daunting challenge and not always easily accomplished in our cost-conscious industry. Production equipment is so asset intensive that automation is critical to keeping the tools productive. When a piece of equipment costs millions of dollars, we simply must achieve high utilization rates and prevent bottlenecks. Often we’re captive to historical thinking and limited by those automation systems and processes that inhibit innovation.

Ultimately, we are in the business of selling wafers and die. The much-talked-about Industry 4.0 can be interesting only if it supports applications that help deliver products on time and with a fair return on investment.

The tough questions for chipmakers are how to (1) improve productivity, (2) create a roadmap so production engineers can go off and create something useful, (3) develop methods for making people more productive, and (4) help production engineers work as a team (as opposed to standalone entities).

Semiconductor Parallels to Autonomous Driving

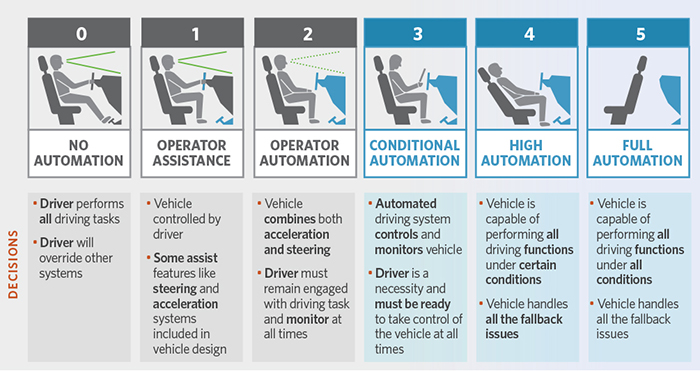

The Society of Automotive Engineers (SAE) has defined six levels of automation leading to autonomous driving, from absolutely no automation to full automation. These definitions certainly apply to automation in semiconductor fabs as well. After all, autonomous vehicles involve software and sensors providing data from surrounding cars with real-time responses, as well as safety goals and objectives to reduce the cost of getting from point A to point B (figure 1).

Figure 1. The path to full automation in the fab in many respects parallels the progressive levels of automation required for autonomous vehicles. (Source: The Society of Automotive Engineers)

The SAE’s definition starts with no automation at Level 0 and then moves to Level 1, where the automobile itself makes some real-time decisions, such as cruise control regulating the acceleration and deceleration of the car, with the driver as the backup plan.

At Level 2, the driver is still in charge, but automation systems start to work together. In the transition to Level 3, the driving system takes ownership of some controls, and the human driver is the fallback plan. At Level 4, the vehicle handles situations it hasn’t encountered before and is the fallback system for many scenarios. With true full automation at Level 5, the vehicle takes over in every way, and the steering wheel and gas pedal are put away for all scenarios.

From Reactive to Self-Actuating

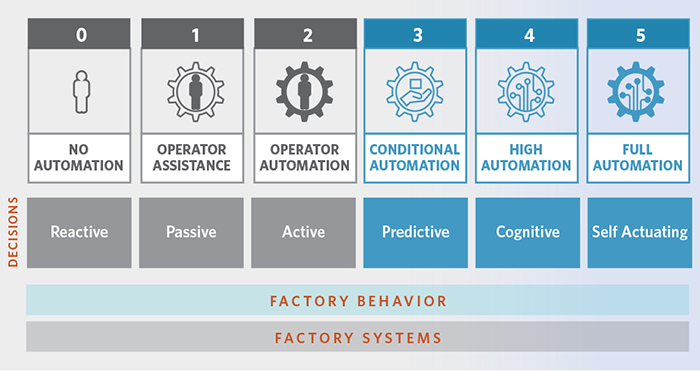

Inside the fab today, the automation levels are similar, as we work from completely reactive, to cognitive, and then to self-actuating systems (figure 2).

Figure 2. To achieve the goal of a fully automated semiconductor fab, progressive levels of automation are required. Level 3 is where many manufacturers are moving today. (Source: Applied Materials)

During the semiconductor industry’s Level 1, we saw the adoption of automated materials handling systems (AMHS), the ability to track yields and defects, and some preventive maintenance. At Level 2, fabs adopted real-time dispatching and R2R control.

Level 3, where many manufacturers are moving today, attempts to achieve the first phases of full automation, including figuring out how to bring in real-time scheduling and predictive techniques. With faster processing speeds now available, companies are seeking to apply machine learning. Level 3 is a proving ground for applications that run on these new technologies.

At Level 3, companies begin to develop their digital twins and decide what components can or cannot move to the cloud. As these companies look down the road to their end goal, realizing that the processes and systems of yesterday aren’t necessarily going to work tomorrow, they will face a steeper learning curve than ever before in building user trust in the technology.

The move to Level 4 is significant because this is where the software must implement requirements never adopted before in the fab and, by adopting these requirements, make good decisions. The systems at this level of automation take in data, and then in real time, make decisions that improve productivity. Just as autonomous vehicles must make decisions in real time for safety reasons, Applied Materials is working with early adopters to enable real-time decisions that optimize business practices.

Level 5, full automation, depends on the ability to determine whether the weakest part of the system works. If the weakest link doesn’t work, then the whole system will fail.

Opportunities For Adding Value

We have an opportunity to develop new methods that can provide additional value for customers. For example, customers want automated planning systems, which bring measurable value through an improved ability to react to shifting market demands. Currently, resource planning is a manual process, and it takes days to update plans which, in an automated system, could be accomplished in minutes. Another industry challenge now facing us is that data coming from factories is often inconsistent. Data quality is also a factor that needs to be addressed to take positive steps forward.

Safe and Sound

Other obstacles to technology adoption exist. A huge obstacle is data security, which impacts adopting the cloud. In complex manufacturing, managers regard their data as equivalent to their intellectual property (IP). To leverage the benefits of the cloud as an industry, we need to differentiate what is IP and what is not. Few use a public cloud now, but semiconductor companies are starting to define what data analysis techniques they can do in the cloud and what can be done on premises.

Companies have been asking, “What should or could I do with the cloud?” However, recently we have witnessed a change of attitude. Applied Materials is ramping up its investment, and management has engaged with large manufacturers to capture drivers and inhibitors to leveraging cloud technology. We believe this transition will happen when manufacturers identify how the new technologies and applications will improve their economics. And at this juncture, they will start to use the cloud.

For comparison, recall for a moment the industry’s concerns when moving from UNIX operating systems to Windows for mission-critical systems. Windows was cost-effective and matured, encouraging adoption. The same will happen with the cloud.

Meanwhile, without compromising security, Applied Materials is working with customers to develop useful techniques, such as dynamic scheduling, full automation scenarios, next-generation run-to-run control, and quality scenarios. These types of applications increase the operational productivity of the factory and move us closer to Level 4 automation.

Final Thoughts on Innovation

Innovation is a key part of the culture in any successful company. Managing change takes a bit of courage and the willingness to support new ways of doing things. Lack of innovation fuels stagnation, which has proven to leave many behind.

To manage this change and make possible the shift to high automation, Applied Materials is investing in and looking for early adopters to test these concepts. We believe our customers want to work on these new technologies with partners, so they can be ready to deal with change and achieve significant business benefits.

David Hanny is marketing director for Applied’s Automation Products Group. For additional information contact him at david_hanny@amat.com.